Advantages

Niagara Cutter tools deliver longer tool life and faster material removal rates, reducing production costs and downtime. Their American-made products combine proven geometries with advanced coatings to handle demanding applications from aluminum to hardened steels.

Extended Tool Life

Niagara Cutter’s advanced geometries and coating technologies provide longer cutting edge durability, reducing tool changes and lowering per-part costs in production environments.

Versatile Material Compatibility

Their tools perform across a broad range of materials from soft aluminum and plastics to hardened steels and exotic alloys, making them suitable for diverse manufacturing applications.

Consistent Performance

American manufacturing with strict quality control ensures reliable, predictable results that help machinists maintain tight tolerances and reduce scrap rates.

Choose your cutter

Selecting the right cutter depends on your material type, machining operation, and desired finish quality. Consider factors like workpiece hardness, cutting depth, spindle speed capabilities, and whether you need roughing or finishing performance.

N67345 Cobalt Steel Ball Nose End Mill

This 1/2″ diameter cobalt steel ball nose end mill features a TiCN coating and 4-flute design with 30-degree helix angle, suitable for both roughing and finishing operations in a variety of materials with its Weldon shank and 3″ overall length.

N85729 Carbide Square Nose End Mill

This 0.188″ diameter solid carbide square end mill with TiAlN coating delivers both roughing and finishing capabilities through its 4-flute, 30-degree helix design for precise metalworking applications.

N56017 Carbide Ball Nose End Mill

This 0.063″ cutting diameter carbide ball nose end mill with TiAlN coating features a 4-flute, 30-degree helix design on a 0.125″ shank, providing roughing and finishing performance in a compact 1.5″ overall length for detailed work.

N46420 Carbide Square Nose End Mill

This 3mm diameter solid carbide square end mill with AlTiN coating offers dual roughing and finishing capabilities through its 4-flute, 30-degree helix configuration in a 39mm overall length format.

N61479 Carbide Square Nose End Mill

This 3/4″ diameter solid carbide square end mill with TiCN coating features a high 45-degree helix and 2-flute design for finishing operations in a 4″ overall length configuration.

N86006 Carbide Square Nose End Mill

This 0.188″ diameter solid carbide square end mill with TiAlN coating provides both roughing and finishing capabilities through its 3-flute, 30-degree helix design in a compact 2″ overall length.

N86026 Carbide Square Nose End Mill

This 1/2″ diameter solid carbide square end mill with TiAlN coating offers dual roughing and finishing performance through its 3-flute, 30-degree helix configuration in a 3″ overall length format.

N85681 Carbide Square Nose End Mill

This 0.156″ cutting diameter solid carbide square end mill with TiAlN coating delivers both roughing and finishing capabilities through its 4-flute, 30-degree helix design on a 0.188″ shank for machining applications.

N46412 Carbide Square Nose End Mill

This 1mm cutting diameter solid carbide square end mill with AlTiN coating provides both roughing and finishing performance through its 4-flute, 30-degree helix design on a 3mm shank in a 39mm overall length format.

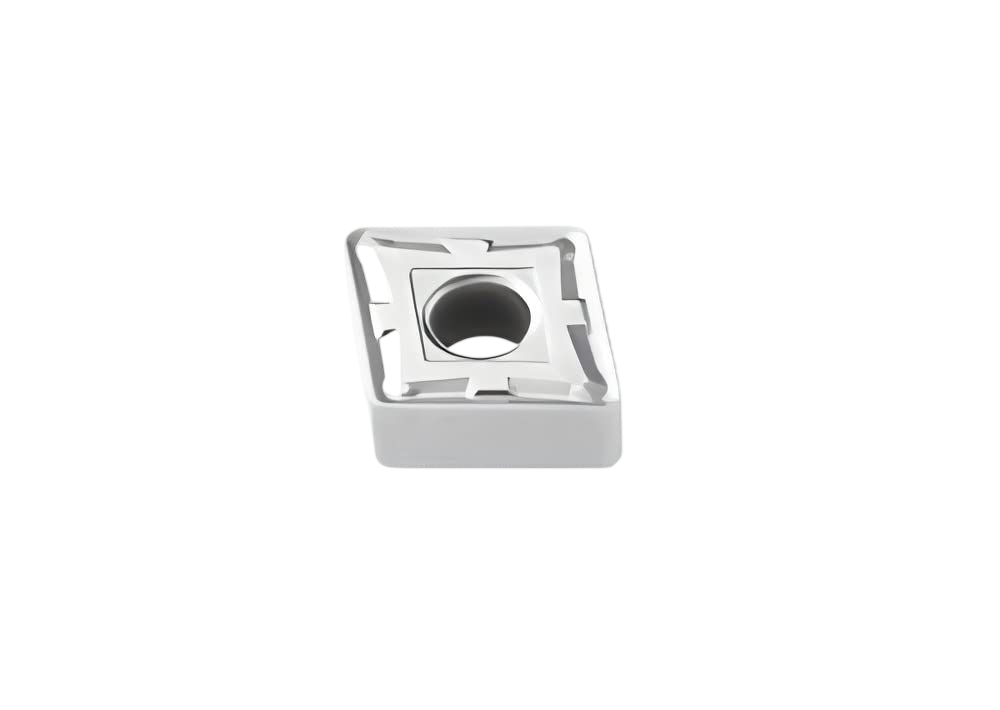

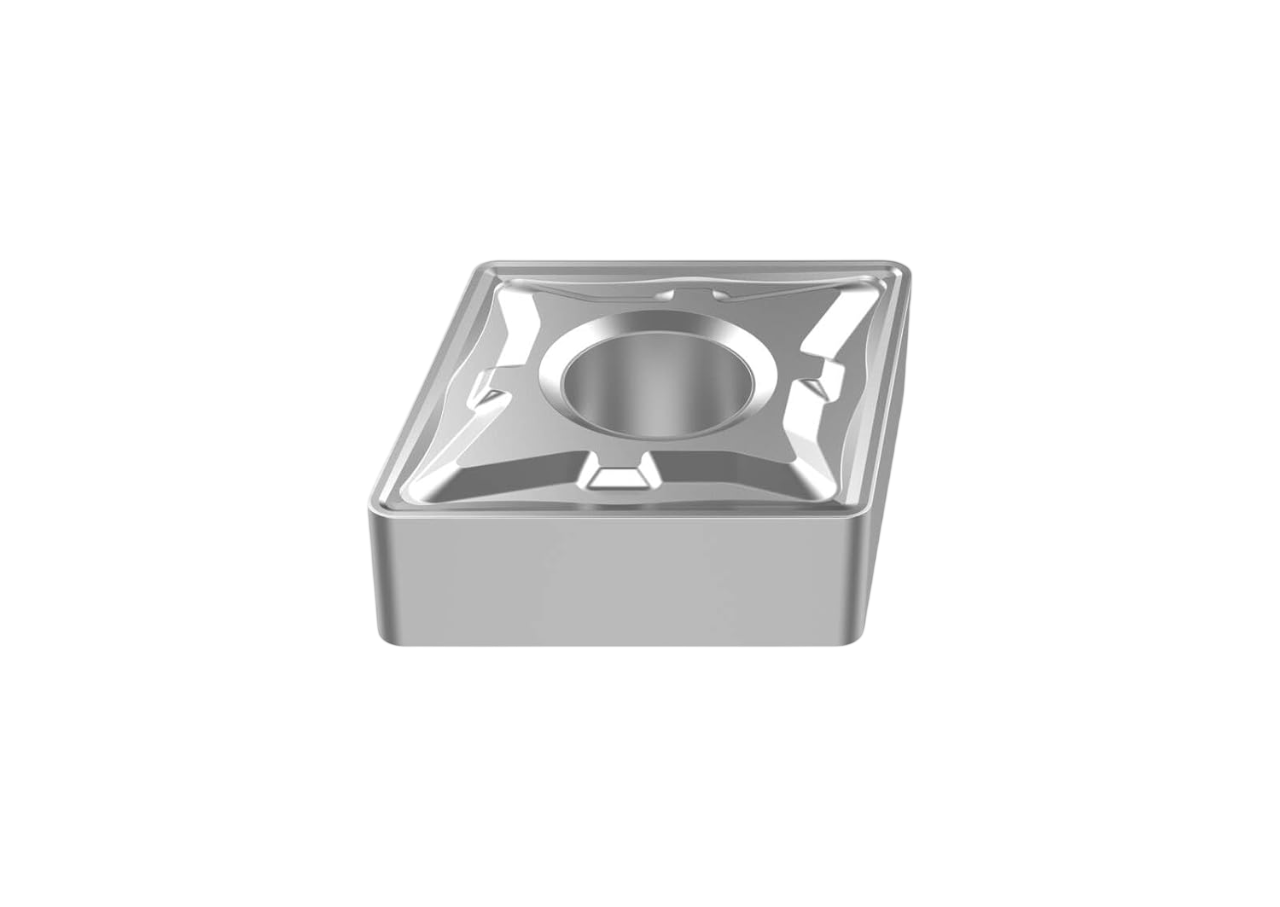

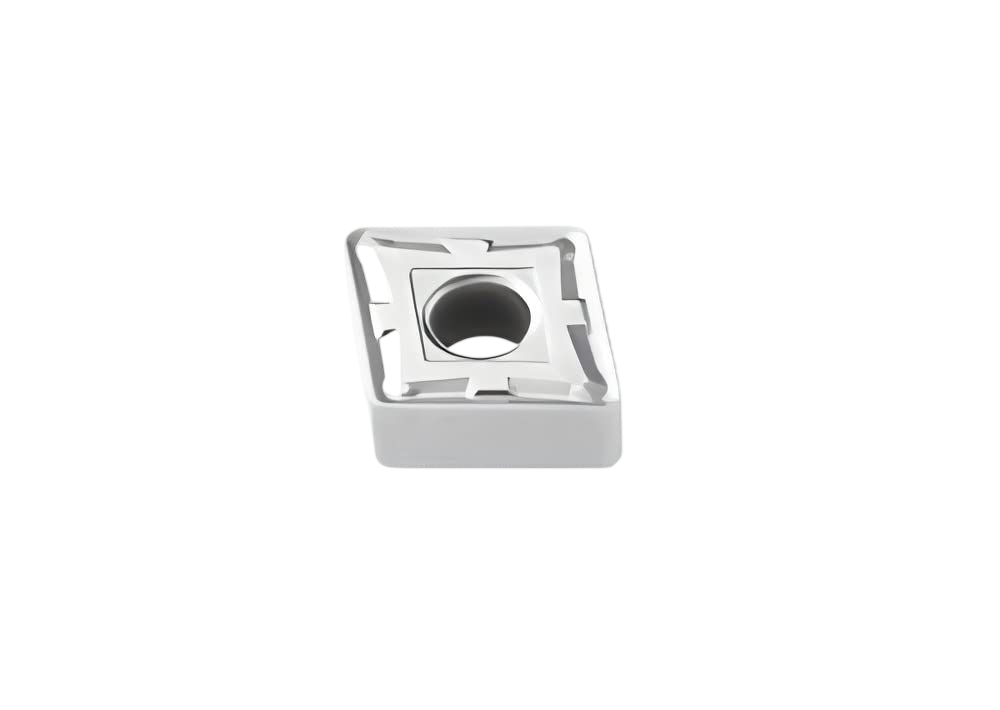

CNMG432-M3 TP2501 Carbide Turning Insert

This CNMG432-M3 carbide turning insert features an Al2O3 CVD coating for reliable performance in general turning applications across a range of materials.

CNMG432-M5 TP2501 Carbide Turning Insert

This CNMG432-M5 carbide turning insert with Al2O3 CVD coating provides durable cutting performance for general turning operations in various workpiece materials.

CNMG432-M3 TP3501 Carbide Turning Insert

This CNMG432-M3 carbide turning insert features a Ti(C/N)/Al2O3 CVD coating for improved wear resistance and extended tool life in general turning applications.

Features

Niagara Cutter tools incorporate variable helix geometries, advanced coating technologies, and optimized flute designs that improve chip evacuation and reduce cutting forces. Their product line includes tools with application-specific features like corner radius designs for strength, high-helix angles for aluminum, and reinforced cores for heavy-duty roughing operations.

Advanced Coating Options

Multiple coating choices including TiAlN, AlTiN, and nACo provide heat resistance and reduced friction for different material applications and cutting conditions.

Optimized Flute Designs

Variable helix angles and core geometries improve chip evacuation, reduce chatter, and allow for aggressive cutting parameters in both roughing and finishing operations.

Wide Size Range

Tools available in fractional, metric, and micro-diameter sizes from 0.005″ up to several inches, accommodating everything from intricate medical components to heavy industrial parts.

Application-Specific Geometries

Purpose-built designs for specific operations like high-efficiency roughing, ball nose profiling, corner radius milling, and high-feed machining strategies to maximize productivity in different scenarios.

Overview

Niagara Cutter is an American manufacturer specializing in cutting tools for metalworking and machining applications. Their product range spans solid carbide end mills, HSS tools, drills, and indexable cutters used across industries requiring reliable metal removal and finishing solutions.

About brand

Niagara Cutter is a leading American manufacturer of cutting tools, established in 1954 in Buffalo, New York. For nearly seven decades, the company has built a reputation for producing high-quality end mills, drills, and metalworking tools that serve industries ranging from aerospace and automotive to medical device manufacturing and general machining.

The company maintains its manufacturing operations in the United States, with facilities that combine traditional methods with modern CNC grinding technology. This domestic production allows for quality control throughout the manufacturing process and quick response times for customer needs.

Niagara Cutter’s catalog includes thousands of standard and specialty cutting tools. Their offerings span solid carbide end mills, high-speed steel cutters, indexable tooling, drills, reamers, countersinks, and thread mills. The company designs tools for specific materials and applications, from soft aluminum to hardened steels and exotic alloys used in demanding aerospace applications.

The company focuses on practical tool design that addresses real-world machining challenges. Their tools feature optimized geometries for chip evacuation, variable helix angles to reduce chatter, and multiple coating options to extend tool life and improve cutting performance. Product lines are organized by application, making it straightforward for machinists to find the right tool for their specific needs.

Niagara Cutter serves a broad customer base across multiple sectors. Aerospace manufacturers rely on their tools for machining titanium and heat-resistant alloys. Automotive shops use them for high-volume production work. Medical device manufacturers depend on their micro-diameter tools for intricate components. Job shops appreciate the versatility across different materials and operations.

The company continues to develop new products based on evolving machining technologies and customer feedback. Their engineering team works on improving tool geometries, testing new coating technologies, and creating application-specific solutions that help manufacturers increase productivity and reduce costs.

Niagara Cutter provides technical support to help customers select appropriate tools and optimize cutting parameters. Their team offers guidance on speeds, feeds, and troubleshooting to help machinists get the best results from their tools.

Subscribe to get a newsletter

What peoples say about us

Machinists and manufacturing professionals consistently praise Niagara Cutter tools for their durability and reliable performance across various materials and applications. Users report that the tools maintain sharp cutting edges longer than many competitors, resulting in fewer tool changes and lower overall costs in production environments.

Jake Morrison

Customer

I’ve been running Niagara Cutter end mills in my shop for about five years now, and they’ve become my go-to choice for tough materials like titanium and Inconel. The tools consistently deliver 30-40% more parts per tool compared to what I was using before, which makes a real difference in production runs. Their chip evacuation is solid, the performance is reliable from one tool to the next, and the tech support has been helpful when I need guidance on tricky applications.

Marcus Chen

Customer

Switching to Niagara Cutter micro end mills was a game changer for the work on surgical instruments and implant components. Their small diameter tools hold tolerances incredibly well, with significantly less tool breakage compared to other brands tried in the shop. The consistent quality means less downtime, fewer scrapped parts, and the ability to run lights-out operations knowing the tools will perform as expected.

Derek Sullivan

Customer

Niagara Cutter tools run across all the machining centers in the shop for mold and die work, and the difference in tool life is noticeable right away. When you’re cutting hardened tool steels day in and day out, having end mills that stay sharp longer directly impacts your bottom line. Their high-feed cutters have cut cycle times by nearly 20%, and the finish quality straight off the machine means less time spent on secondary operations.

FAQ

Their tools are used across aerospace, automotive, medical device manufacturing, mold and die shops, job shops, and general manufacturing. Any industry that requires metal cutting and machining can benefit from their product range.

Their tools are designed to cut a wide variety of materials including aluminum, steel, stainless steel, titanium, hardened steels, cast iron, exotic alloys, and plastics. Different tool geometries and coatings are optimized for specific material types.

Common coating options include TiAlN (Titanium Aluminum Nitride), AlTiN (Aluminum Titanium Nitride), TiN (Titanium Nitride), and their proprietary nACo coating. Each coating offers different benefits for heat resistance, wear resistance, and lubricity.

Consider your workpiece material, the type of operation (roughing or finishing), depth of cut, and machine capabilities. Niagara Cutter’s technical support team can help recommend specific tools based on your application requirements.

Carbide tools are harder and can run at higher speeds, making them ideal for production environments and harder materials. High-speed steel tools are tougher and more forgiving, often preferred for interrupted cuts, manual machines, or when tool cost is a primary concern.

Yes, they can produce custom cutting tools to meet specific application requirements. Contact their technical team to discuss your needs and specifications.

Speed and feed recommendations depend on material type, tool diameter, depth of cut, and machine rigidity. Niagara Cutter provides starting parameter guidelines with their tools, and their technical support can help fine-tune settings for your specific application.

Properly stored cutting tools have an indefinite shelf life. Keep them in a dry environment, protected from damage, and in their original packaging when not in use to maintain cutting edge integrity.